ABSTRACT

To fulfill the Secretary’s directive in implementing Green TVET institution, Leon Ganzon Polytechnic College established a Mini-Organic Farm using ecobricks to minimize the plastic waste dumped on the environment. Ecobricks uses an empty plastic container filled with non-biodegradable waste. It is an affordable form of recycling method that does not require technology, capital and substantial amount of manpower. Ecobricking promotes circular economy by maximizing the usage of waste materials and converting it into reusable materials. Memorandum was issued to the faculty, staff, and trainees requiring them to submit one (1) piece of ecobrick. The project was included in the Individual Performance Commitment Review (IPCR) of the faculty and staff and integrated during the training. Before the implementation of the project, there are at least 4 kilos of plastic waste/ week collected from offices and laboratory rooms. The activity was able to lessen the plastic wastes collecting 2,220 ecobricks, a total of 3.7 tons. The project was evaluated using an evaluation form with a series of questions about the durability of ecobricks. The activity does not incur any expenses and does not require extensive labor compared to the traditional waste recycling method. With the positive response of the stakeholders, LGPC was motivated to become a sustainable green TVET institution.

Keywords: ecobrick, circular economy, plastic pollution, green initiative

A. INTRODUCTION

Philippines is filled with white sand beaches and astounding landscapes but we are bombarded by the accumulating plastic waste on the land, clogging seashore and plastic waste spilling into the bodies of water. In the study of World Wide Fund for Nature (WWF) Philippines recorded that at the national level only 40% of packaging waste is collected and only 9% of the plastic waste is recycled. This is the outcome of not strictly implementing and institutionalizing recycling practices at the ground level. This is supported by the study of World Bank Group (2021) states that Philippines generates an estimated 0.75M metric tons of mismanaged plastic entering the ocean every year and is the third-largest polluter in the world. Plastic packaging is habitually used; despondently it imposes detrimental effects on the environment. Ujeh, K. (Undated) emphasized that plastic waste takes many years to decompose. Ujeh added that when plastic bags perish under sunlight it releases toxic substances into the soil and when burned emits harmful substances that cause air pollution.

Ecobricks is a reusable building block created by solid non-biodegradable waste placed inside the plastic bottle to a set density (Low, 2018). The empty bottles are filled with non-biodegradable materials such as plastic wastes thus preventing it from degrading into harmful chemicals like methane and microplastics.

The method is an alternative low energy solution apart from recycling that requires technology, capital and substantial amount of manpower. Ecobricking promotes circular economy by reusing the products before being recycled or composted (Gozum, 2020). As described by Geissdoerfer, M. (2016), the circular economy is a regenerative system in which waste emission and energy leakage are minimized by slowing, closing, and narrowing material and energy loops.

With the enormous problem with plastic pollution, government agencies invested in measures to lessen plastic waste. Instead of purchasing materials for construction, the Leon Ganzon Polytechnic College (LGPC) uses ecobricks weighing 1.5kg per piece as building materials in Mini-Organic Farm. This project aims to create awareness among its stakeholders of the potential uses of ecobricks and to lessen the plastic waste being dumped into the environment.

B. DEVELOPMENT AND IMPLEMENTATION OF THE BEST PRACTICE

- Environmental Friendly Practices

The establishment of Mini-Organic Farm made of ecobricks is one of the green initiatives of LGPC. The activity started on January 06, 2021, guided by the Memorandum, faculty and staff are required to submit at least one (1) piece of ecobrick. In addition, trainees are also required to submit one (1) piece of ecobrick for every qualification they attend in LGPC.

This project uses 1.5L empty polyethylene terephthalate (PET) bottles filled with dry-rolled plastic wastes. A wooden stick or metal stick that is about twice the length of the bottle is used to firmly pack the plastic. The finished output was weighed to conform to the required minimum weight. Figure 1 shows the step-by-step procedures of ecobricking done by the LGPC trainees and personnel.

2. Funding Source

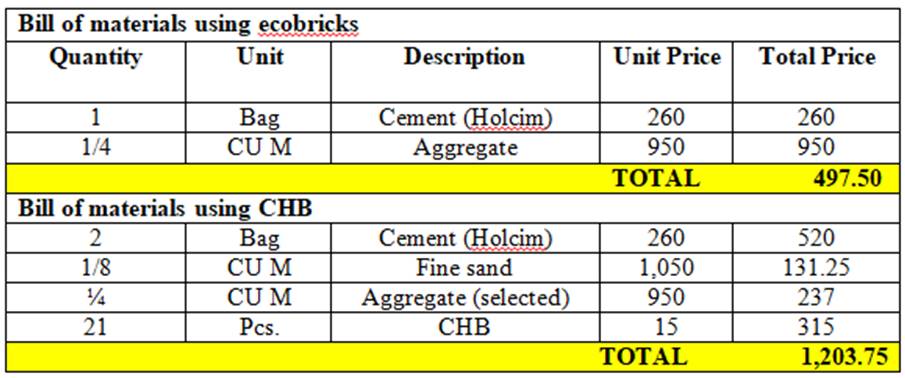

The ecobricks used in Mini-Organic Farm are empty plastic bottles mostly from the stakeholders’ households, offices, and laboratory rooms thus it only incurs minimal expenses. The expenses spent in the project are for the purchase of cement and construction aggregate for the foundation of the garden. This is an initiative of LGPC to promote the circular economy by remanufacturing and reusing plastic waste and converting it into ecobrick. The institution was able to spend P497.50 only on the construction of the Mini-Organic farm using ecobricks and a difference of P706.25 compared to CHB as shown in Table 1. Moreover, the project does not require extensive labor but rather it is an individual and collective effort of LGPC stakeholders.

Table 1. Comparison of Materials for Garden Flat Construction (1M x 3.6M) using ecobriocks and concrete hollow block (CHB).

3. Promotion and Advocacy

To institutionalize the green initiative to its internal and external customers, a Memorandum was issued to the faculty, staff, and trainees. Furthermore, for the faculty and staff, the submission of ecobrick per rating period is part of the Individual Performance Commitment. During the Training Induction Program (TIP) on September 21, 2021, the project was introduced to the Diploma trainees (Figure 2). The activity is documented by taking photos and videos on the development of the project and presented at every faculty and staff meeting.

4. Sustainability of Green Institutional Culture

With the intention to create LGPC as a sustainable green institution the project was included in the Individual Performance Commitment Review (IPCR) for the second semester July-December 2021. Apart from this, LGPC believes in the advocacy of “one household at a time” thus the activity was integrated during trainings encouraging the household of each trainee to do the same. The project is not just a mere obligation but rather became a part of the organizational culture.

5. Evaluation Procedure

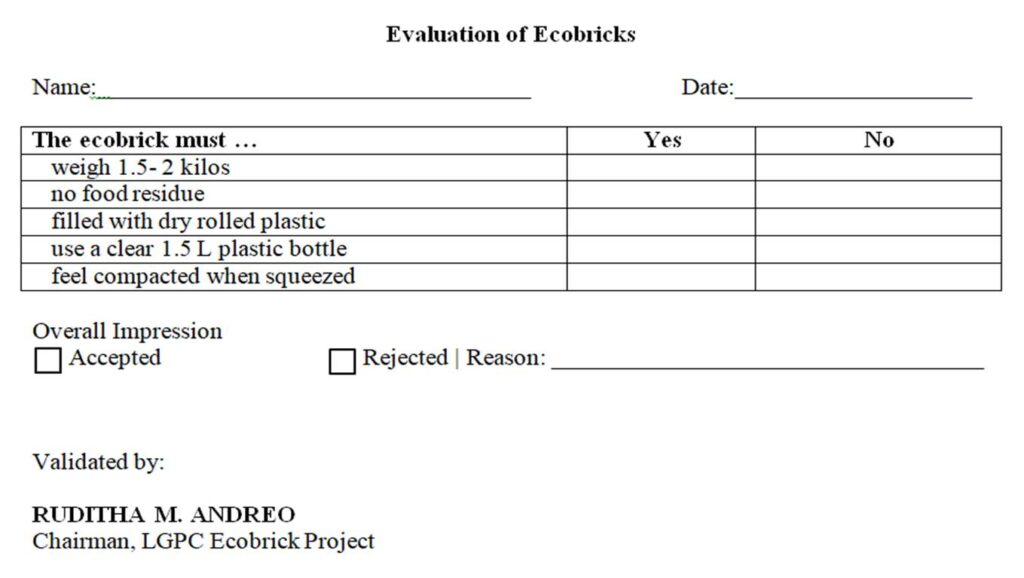

The project was validated by Mrs. Ruditha Andreo, chairman of LGPC Ecobrick Project using the evaluation checklist (Figure 3) before utilizing it into construction materials to maintain its durability. The checklist consists of series of questions that tackle the weight, density, and size of ecobrick (Figure 4) it was administered directly to the respondent and was given feedback after the thorough analysis.

C. RESULTS AND DISCUSSION

- Project Capabilities and Limitations

The said activity was able to lessen the plastic wastes being dumped in the environment. After eight (8) months the institution collected 2,220 ecobricks, a total of 3.7 tons. Before the project was implemented, LGPC disposed of at least 4 kilos of plastic waste/ week coming from offices and laboratory rooms. It was found out that ecobricks are sturdy enough in any weather circumstances, it does not brittle as long as it meets the minimum density requirement. This project motivated the faculty and staff to change the “take, make, waste” mentality thus reducing the burden on the environment.

Moreover, the institution believed that this project alone cannot resolve the ongoing environmental problems however, with student involvement and support from its stakeholders LGPC is just one step away from its goal to become a sustainable green TVET institution.

2. Project Evaluation

The implementation of the project was realized. LGPC was able to construct a Mini-Organic farm out of ecobricks (Figure 5). Based on the evaluation conducted by the committee, all of the ecobricks submitted passed the minimum requirement and can stand in any weather condition. Apart from this, 100% of the stakeholders complied with the said activity.

D. ISSUES, CHALLENGES AND RECOMMENDATIONS

- Issues and Challenges

A sudden change in requirement or policy in an organization for its growth is inevitable. During the first month, the activity received negative remarks because this is just another task or responsibility to conform. However, after a series of meeting with the stakeholders and presenting the advantages of the project and the intention to become a green TVET institution. The activity was enthusiastically accepted, in fact faculty and staff appreciate the objective of ecobricking and the concept of the circular economy. The administration believes that with proper communication and being open with the suggestion a transformation is not impossible.

2. Recommendations

Based on the result of the project, the following activities are recommended:

- conduct of information dissemination about ecobricking in the broader audience such as caravan or workshop during World Environmental Health Day;

- partner with adjacent barangays by installing organic garden out of ecobricks; and

- coordinate with the Local Government Unit (LGU) to implement or adapt the concept of ecobricking through a contest among barangays and elementary schools.

REFERENCES

Geissdoerfer, M. et al. 2016. The circular economy- A new sustainability paradigm?.Journal of Cleaner Production. Retrieved from https://www.sciencedirect.com/science/article/abs/pii/S0959652616321023?via%3Dihub on September 20, 2021

Gozum, I. 2020. Communities bear the weight of the Philippines’ waste problem. Manila Philippines: Rappler. Retrieved from https://www.rappler.com/environment/tackling-plastic-waste-from-communities on September 17, 2021

Low, C. 2018. Ecobricks: Plastic Solved. The Sustainability Project. Retrieved from https://thesustainabilityproject.life/blog/2018/10/07/ecobricks-plastic-solved/ on September 20, 2021

Ujeh, K. Undated. The negative environmental effects of plastic shopping bags. London: International Bar Association. Retrieved from https://www.ibanet.org/article/76F8D2A9-1A1D-4A2F-8A6F-0A70149FD4D5 on September 20, 2021

World Bank Group 2021. Market Study for the Philippines: Plastics Circularity Opportunities and Barriers. Marine Plastics Series, East Asia and Pacific Region. Washington DC. Retrieved from

Written by: Ariel Reckonete B. VIllanueva and Joanne Michole V. Biboso